|

|

|

|

Product Catalogue

Certifcates

User Manual

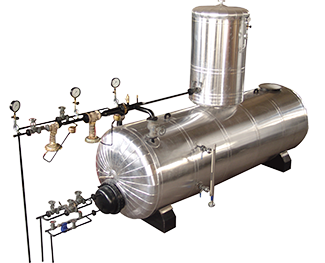

THERMIC DEGASSER

Thermic Degasser is used to remove molten gases such as carbon dioxide CO2 and hydrogen sulfide H2S in water. For the removal of molten gases in water; The water enters the unit from the distribution diffuser at the top of the Deaerator. The water drains downwards, coming into contact with the rings that are filled in the upper tower of the Deaerator. While it is filtering downwards, low pressure steam from the deaerator is given from the bottom up to ensure the contact of the water with the steam. Steam absorbs the dissolved gases in the water and blows them away. Thus, the gases in the water are removed with the reverse flow principle and the purified water is stored at the bottom of the Deaerator.

There are two important effects that cause corrosion and cavitation in steam systems. Hardness and stone-forming materials such as lime in the boiler feed water are corrosive gases such as Oxygen (O2) and Carbon Dioxide (CO2).

If the steam boiler feed water cannot be purified from these molten gases, the life of the entire system will be shortened, and corrosion and damage will begin in all devices and installations that make up the system, especially the boiler, in a very short time. In addition, CO2 causes excessive corrosion, especially in devices using steam, coils and condensate pipes.

Conventional thermal deaerators operating on the basis of temperature and pressure are especially used in high pressure systems where the rate of fresh feed water is high. These devices also allow the carbonates, which are partially broken down in the condensate tank, to decompose in their own body and release their gases. The operating temperature of these devices is 102 0C - 105 sup>0C, the operating pressure is 0.2 bar - 0.5 bar, and their degassing efficiency is around 96%-99%. Since the temperature is high, the boiler feed pumps should be installed higher than the feed pumps to ensure that they work without causing cavitation. In this type of deaerator system, another part of the heating steam is given directly to the water in the deaerator tank with a special mixing equipment, so that the water boils and leaves its gas, and re-gasification is prevented.

In the Thermic Degasser system, the feed water is pulverized and mixed with steam by passing it through Thermic Degasser pans and its temperature is increased, and thus O2 - CO2 gases are separated from the feed water. The released O2 and CO2 gases are discharged through the Thermic Degasser.

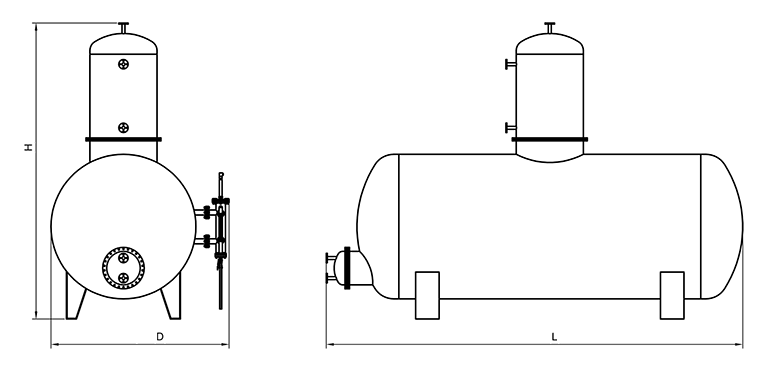

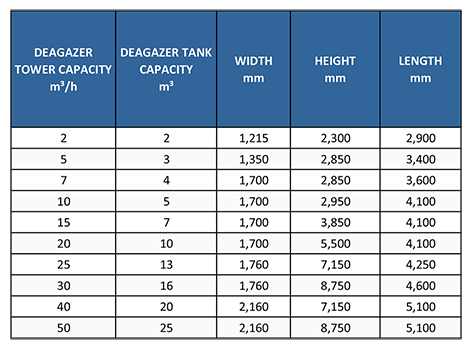

THERMIC DEGASSER DIMENSIONS

AR-GE Group Boiler reserves the right to change values and tables without notice.

AR-GE GRUP KAZAN MAKİNA VE ISI SİSTEMLERİ İMALAT İTHALAT İHRACAT SANAYİ TAAHHÜT TİCARET LTD ŞTİ

Ostim O.S.B. Cevat Dündar Caddesi No:20

Yenimahalle - ANKARA

Telephone : 0 312 354 11 62 - 354 11 72

info@argekazan.com

Corporate

Products

Consumer Services

All rights of this site belong to AR-GE Grup Kazan Makina ve Isı Sistemleri Ltd Şti

Copyright © AR-GE 2020 All rights reserved