|

|

|

|

Product Catalogue

Certifcates

User Manual

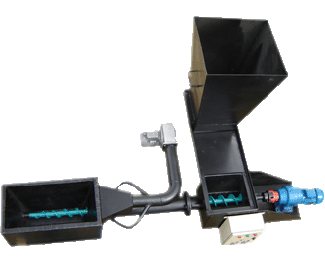

MECHANICAL COAL BURNER

Mechanical Coal Burner; The required air requirement for proper combustion of coal is provided by a radial fan with an aluminum casting body, and coal is transported according to the need thanks to the reducer. Depending on the temperature or pressure, the fan and the reducer are activated and work depending on the automation. In this way, it saves coal.

Since full automation is provided in coal-fired boilers, your staff will be comfortable. Error and waste caused by human factors are minimized. Combustion efficiency is high since the air requirement is provided in a controlled manner. Thus, there will be no problems caused by the chimney. It is environmentally friendly. Particulate matter and smoke emission are lower in the chimney.

OPERATION PRINCIPLE

Automatic system turns on and stops automatically according to pressure or temperature. The stoker system burns all types of coal between 0.5 mm and 30 mm. Since the coal carrier reducer and air fan on the system are connected with the boiler thermostat or pressure switch, the system automatically stops when the boiler reaches the desired value and starts again when it reaches the lower limit of the set values.

The Main Components;

- Charcoal Hopper

- Screwed Conveyor

- Combustion Section

- Control Panel

Charcoal Hopper: It is the part where the hourly fuel of the boiler is stored. There is a sieve on it to prevent foreign substances from entering. The coal filled in the bunker should not be wetted. Wet coal reduces combustion efficiency. It also causes blockages at the entrance to the auger. If the bunker is left empty, smoke can be seen from the bunker. At the same time, the auger may be damaged. Therefore, it is highly recommended not to leave it blank. The sieve above the bunker is placed in the auger to prevent foreign materials and large fuel particles from entering. Therefore, the sieve should not be lifted.

Screwed Conveyor: It is the part obtained by wrapping the leaves on a shaft that carries the coal in the bunker to the combustion chamber.

Combustion Section: It is the part where the combustion event takes place. The coal brought by the helix and the air supplied by the fan mix here and cause combustion to occur.

The points to be considered in stoker are as follows;

- There should be a coal height of at least 10 cm in central boilers on the crucible during combustion.

- This should be ensured by setting the feeding and waiting times on the control panel.

- Do not interfere with the middle part of the crucible.

- The slag accumulated on the sides of the crucible should be removed.

Control panel It is the electronic control panel that provides automatic operation of the boiler.

MECHANICAL COAL BURNER DIMENSIONS

We reserve the right to change AR-GE Grup Kazan values and measurements without notice.

AR-GE GRUP KAZAN MAKİNA VE ISI SİSTEMLERİ İMALAT İTHALAT İHRACAT SANAYİ TAAHHÜT TİCARET LTD ŞTİ

Ostim O.S.B. Cevat Dündar Caddesi No:20

Yenimahalle - ANKARA

Telephone : 0 312 354 11 62 - 354 11 72

info@argekazan.com

Corporate

Products

Consumer Services

All rights of this site belong to AR-GE Grup Kazan Makina ve Isı Sistemleri Ltd Şti

Copyright © AR-GE 2020 All rights reserved